ENG 004 Lecture 14, Nov 13, 2012

Announcements

- Homework #5 due today

- Homework #6 posted after class

- Finish reading Chapter 9

- Office Hours 5-6

Topics

Tolerances

Tolerances are the allowable deviation in size,

location, and geometry of a feature.

The primary role of dimensioning is to control the size or location of a

feature.

Every dimension has to have a tolerance associated with it: X.XX±0.02

Traditional/Size-control Tolerancing

Does not control for the form (geometry) of the feature directly, it only

controls the size or location

Traditional Tolerance Types

Bilateral

Unilateral

Limits of Size

Default Tolerances

Tolerance Zone - Size

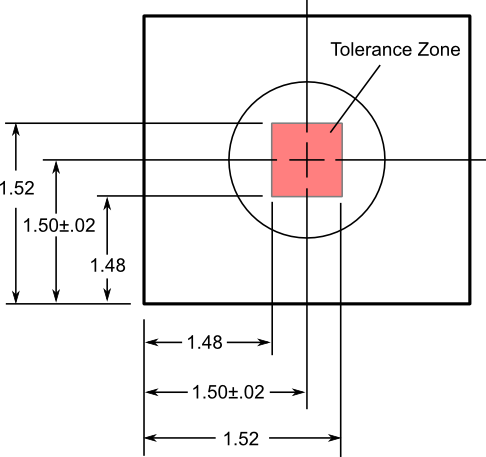

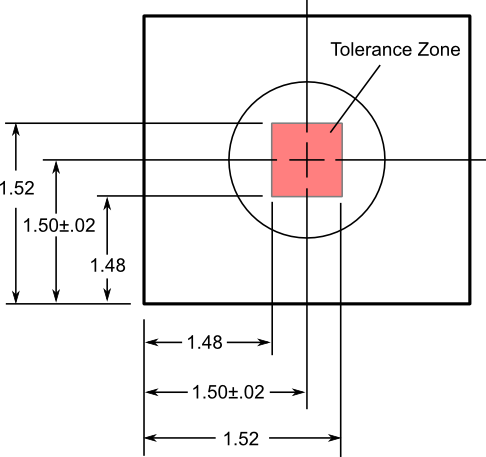

Tolerance Zone - Location

Material Conditions

Maximum Material Condition (MMC)

Size of a feature at one end of its tolerance zone where there is the most

amount of material.

Least Material Condition (LMC)

Size of a feature at one end of its tolerance zone where there is the

least amount of material.

Material Conditions

Tolerance Stackup

Tolerances always add!

0.7±0.2 + 0.5±0.3 = 1.2±0.5

0.7±0.2 - 0.5±0.3 = 0.2±0.5

Functional Dimensioning

Functional Dimensioning

Classes of Fit

An assembly of two parts creates a "fit" whose functional characteristic

is determined by the differences in the parts' associate sizes.

Clearance Fit

The MMC of the hole is always greater than the MMC of the shaft:

MMChole > MMCshaft

Interference Fit

Both the MMC and the LMC of the hole are less than the MMC and LMC of the

shaft, respectively

MMChole < MMCshaft

LMChole < LMCshaft

Clearance and Interference

Transition Fit

Metric Fit Classifications

Metric Fit Notation

Metric Preferred Hole Based System

Minimum hole size is the basic size

Metric Preferred Shaft Based System

Minimum shaft size is the basic size

Metric Fit Note Form

English Preferred Precision Fits

Running and Sliding Fits [RC]

The loosest fits. Used when shaft must move freely in a hole. Always has

clearance, position is not critical.

Clear Locational Fits [LC]

Tighter than RC. Shaft and hole may be same size (line-to-line fit).

Location is more important than RC.

Transition Locational Fits [LT]

Transition between LC and LN. May have slight clearance or may have

slight interference.

Interference Locational Fits [LN]

Can be line-to-line, but almost always shaft is larger than the hole.

Position/location very important.

Force and shrink fits [FN]

Pure interference fits. Used to secure parts together.

English Preferred Precision Fits

Basic Size

Theoretical nominal size to which the tolerance limits are applied.

Basic Hole System

Smallest hole is set as the basic size. Most common due to drill

tooling

Basic Shaft System

Largest diameter of the shaft is assigned as the basic size. Less

popular.

Basic Hole and Shaft Systems

←

→

←

→

/

#