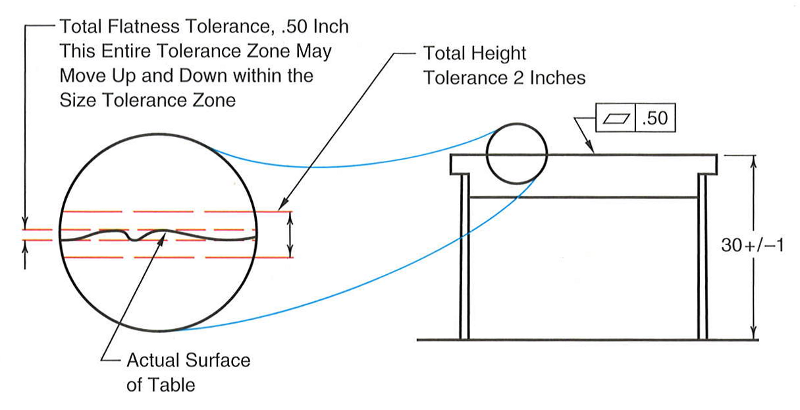

Table Example

Tolerancing is the art and science of using the largest tolerance possible that will still allow a part to function.

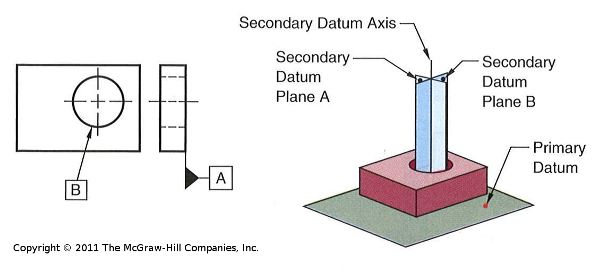

Where only a tolerance of size is specified, the limits of size of an individual feature prescribe the extent to which variations in its geometric form, as well as size, are allowed.

If a feature is dimensioned only with a traditional tolerance, then that tolerance governs all of the tolerances for form. You only specify geomtric dimensions and tolerances to supplement the tradiational size/location tolerance.

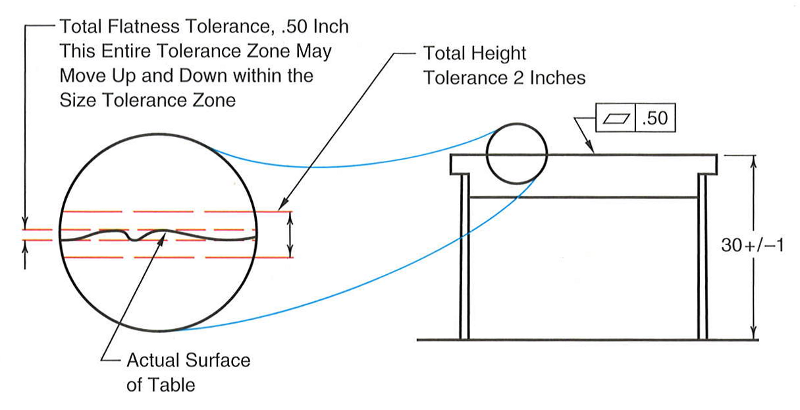

A starting place for a dimension such as a perfect plane, a center line, or a point.

Datums are perfect, ideal constructs

In reality "perfection" of a datum can mean that it is at least 10 times more accurate than the accuracy of the part being measured.

|

|

|

|

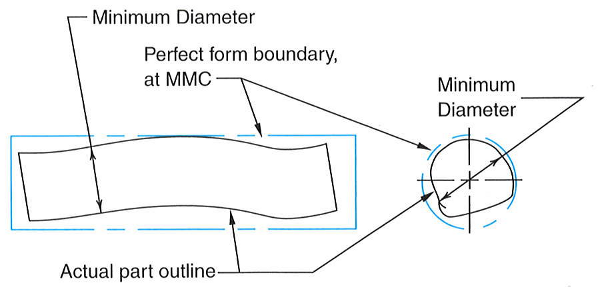

Used to specify the geometric tolerances. It is divided into two or more zones.

|

|

/

#