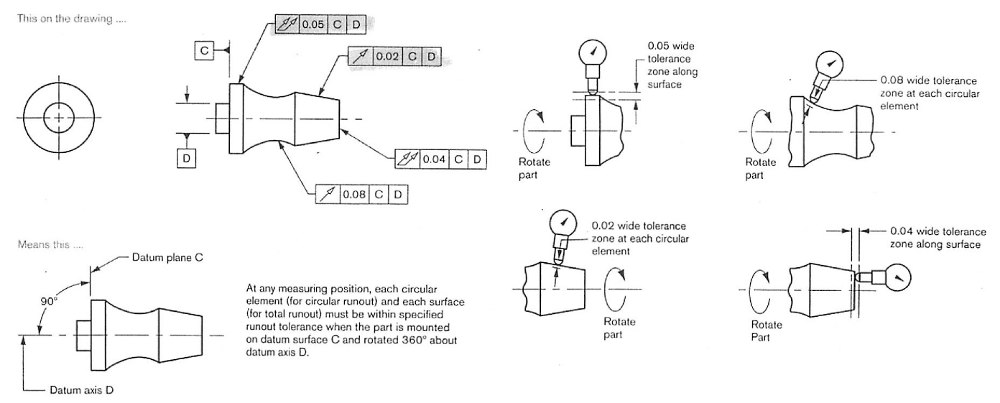

Runout

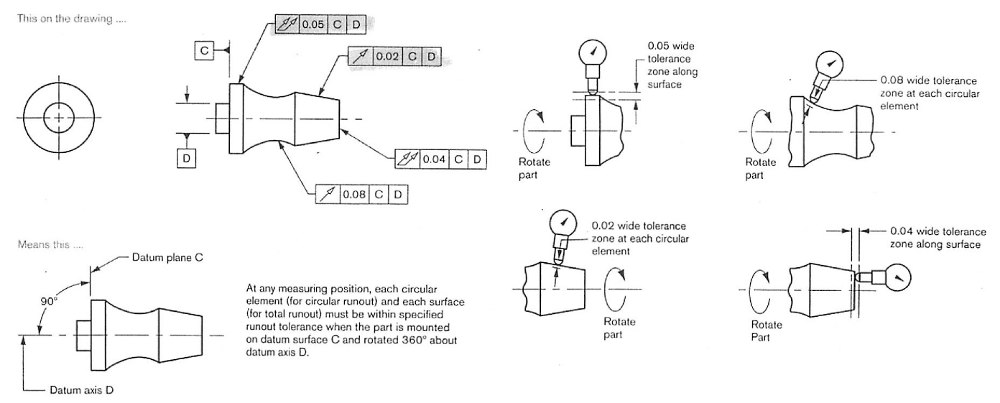

Detail drawings, production drawings, final drawings

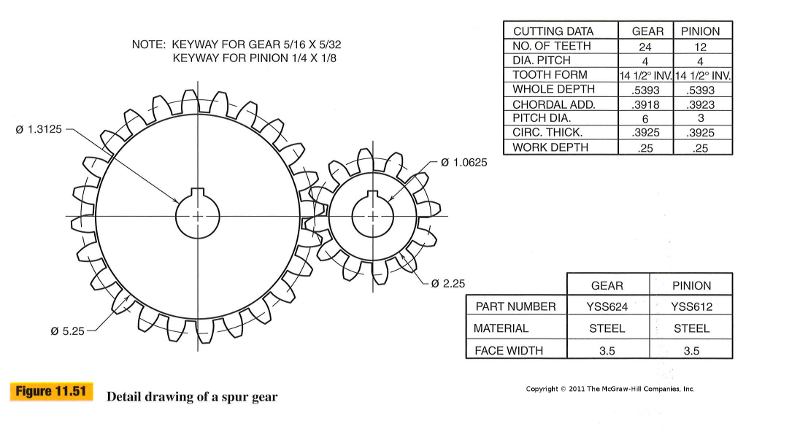

The complete set of standardized drawings specifying the manufacture and assembly of a product based on its design.

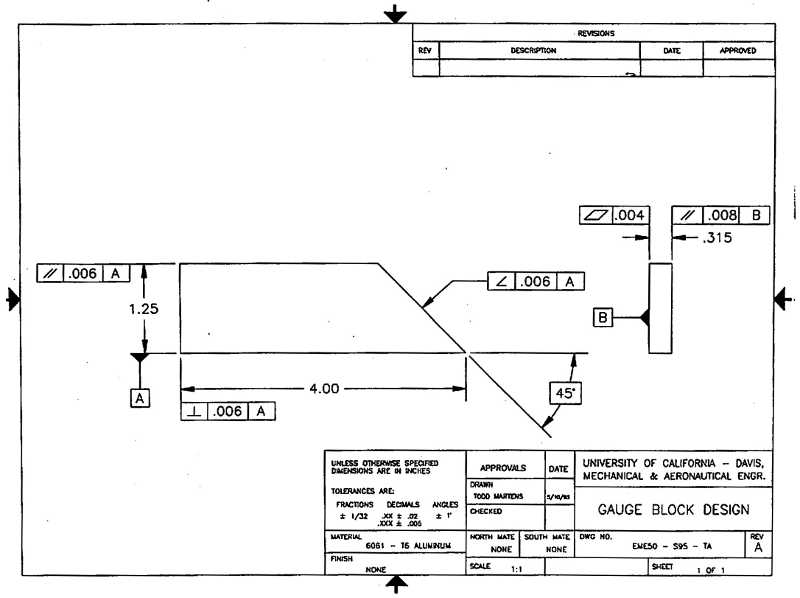

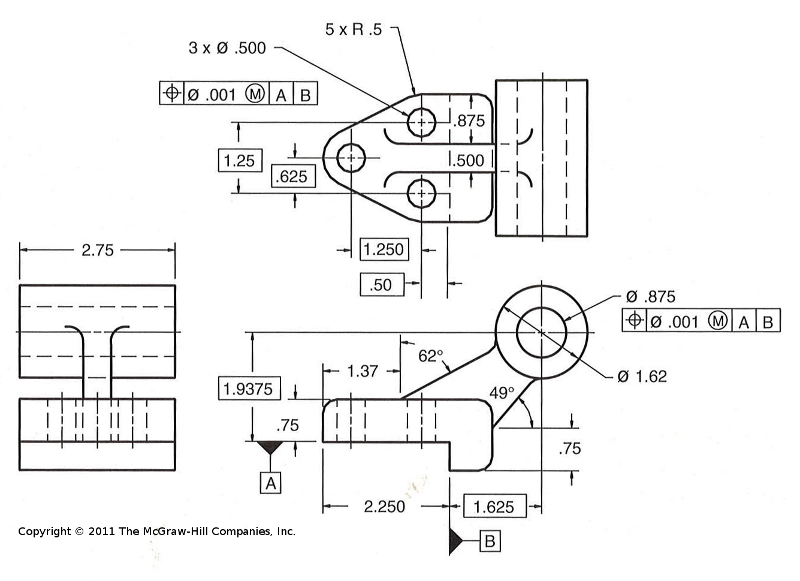

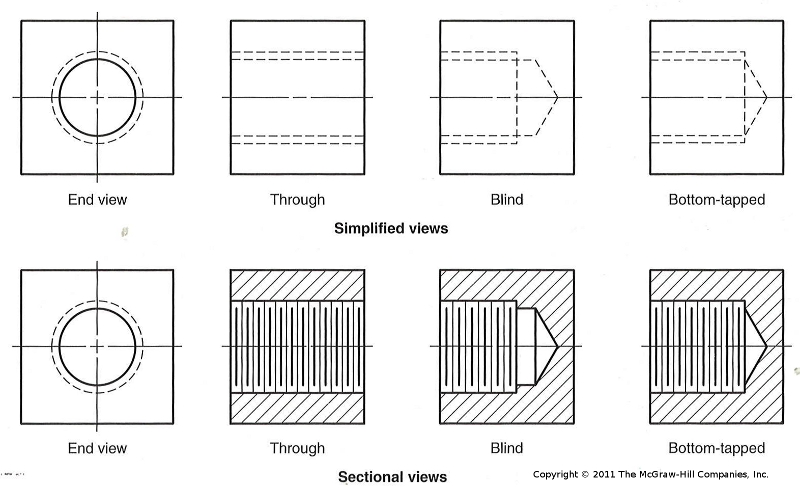

Working drawings are either multi-view drawings of a single part providing all the detail necessary to manufacture the part of an assembly drawing showing how previously manufactured parts are put together.

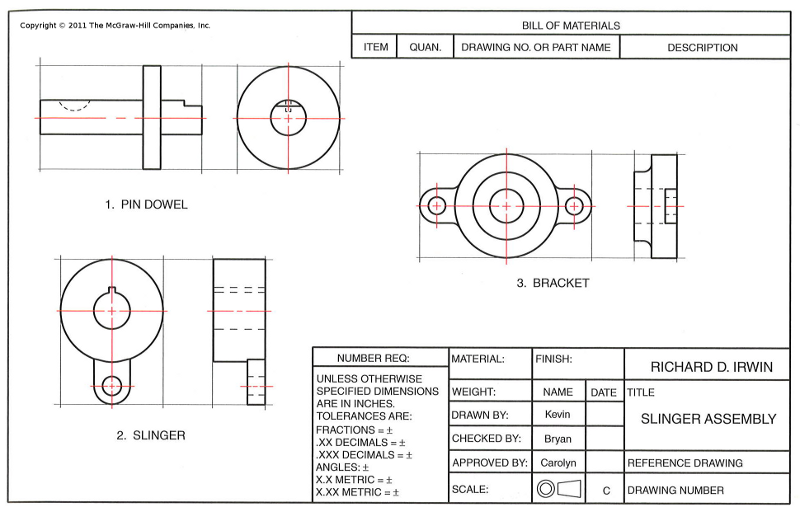

Includes: detail drawings of each non-standard part, an assembly or subassembly drawing showing all the standard and nonstandard parts in a single drawing, a bill of materials, a title block.

are sometimes represented as an exploded pictorial drawing.

Written instructions

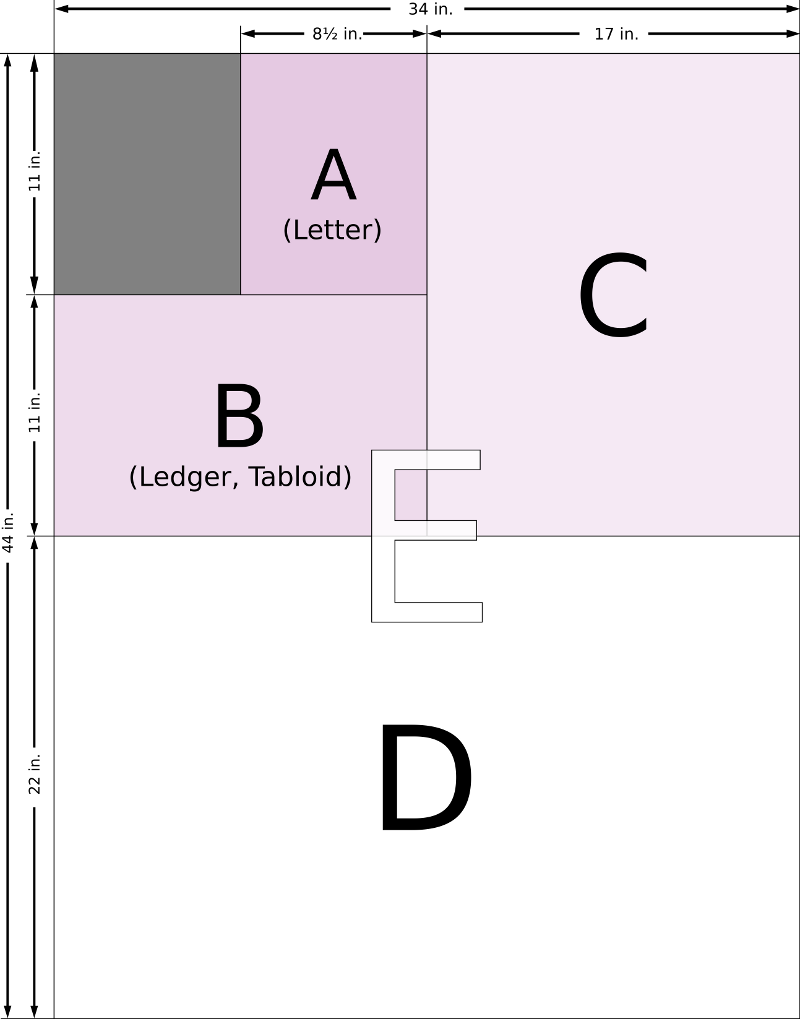

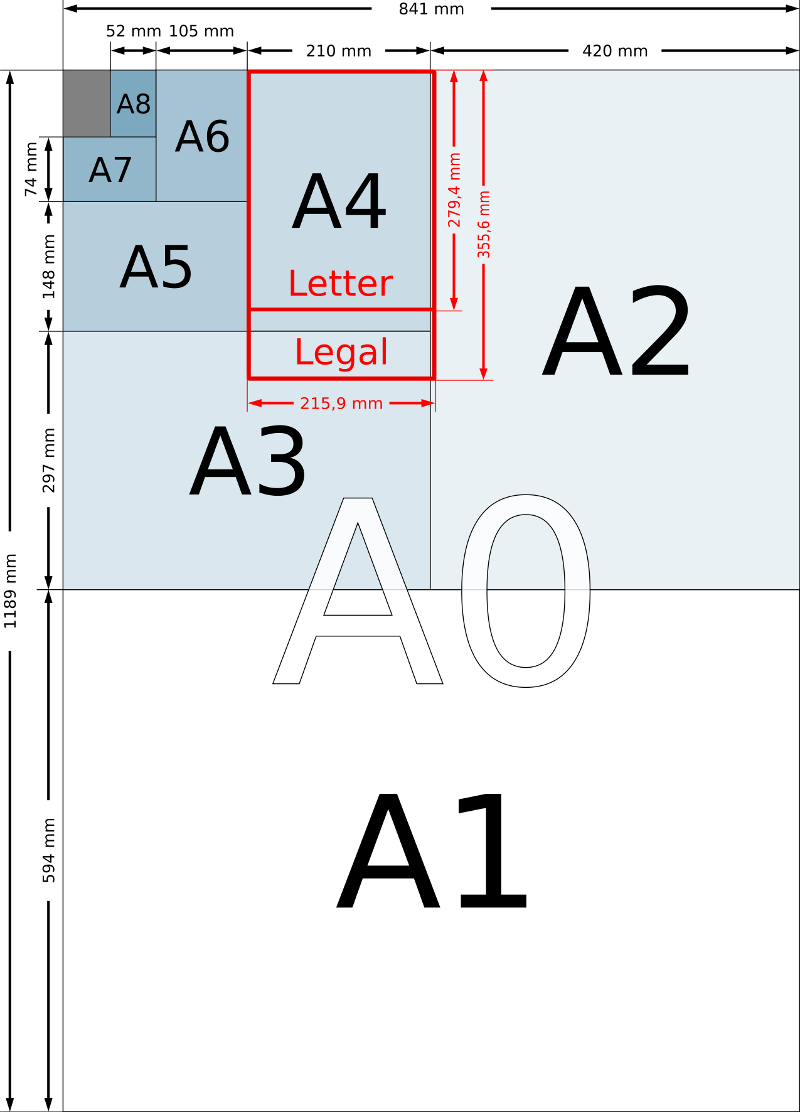

Views should be scaled to fit on the paper.

Block in boundaries of views to space

Stay within the borders

Views should be aligned, if not they should be labeled

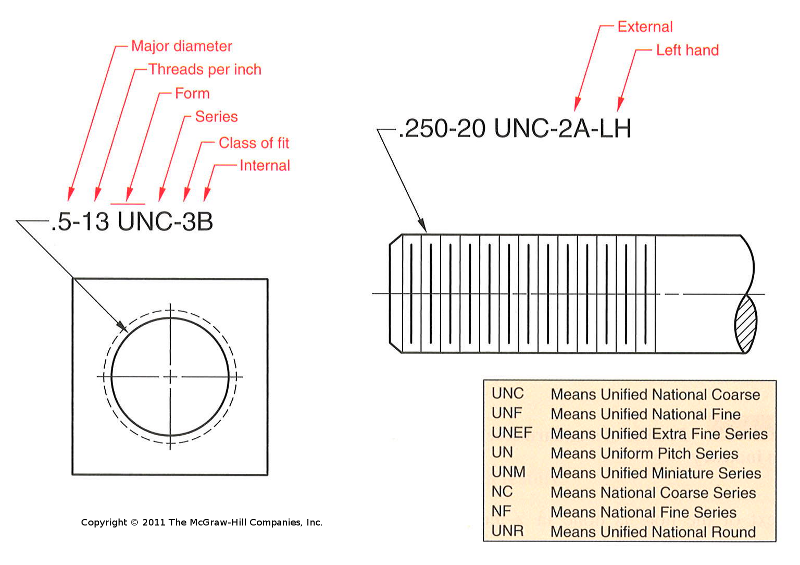

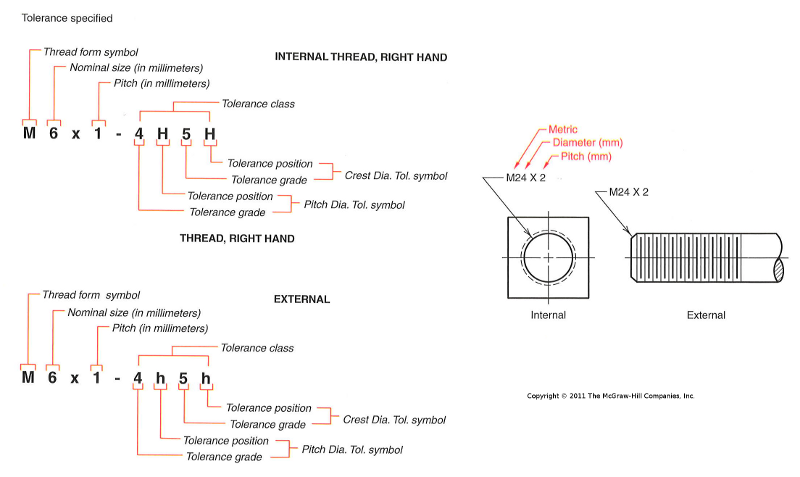

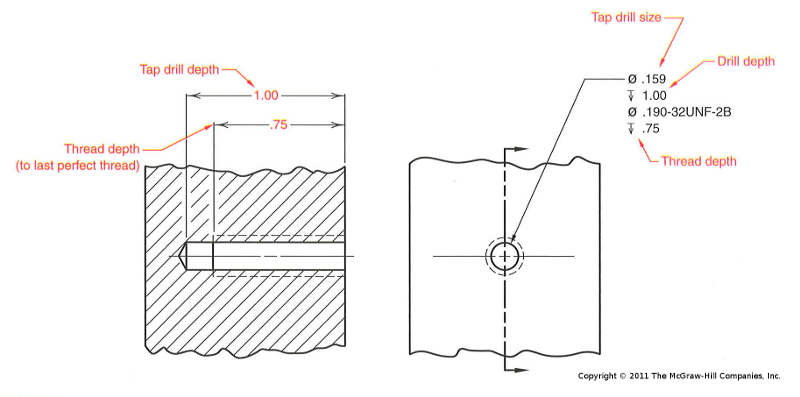

English

|

Metric

|

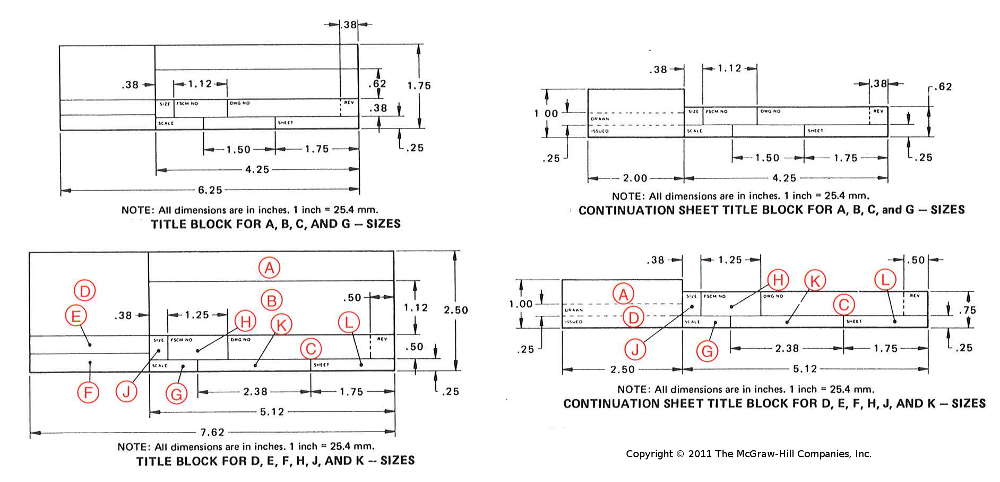

Used to record all the important information necessary for the working drawings.

/

#